A company of the

Group of companies

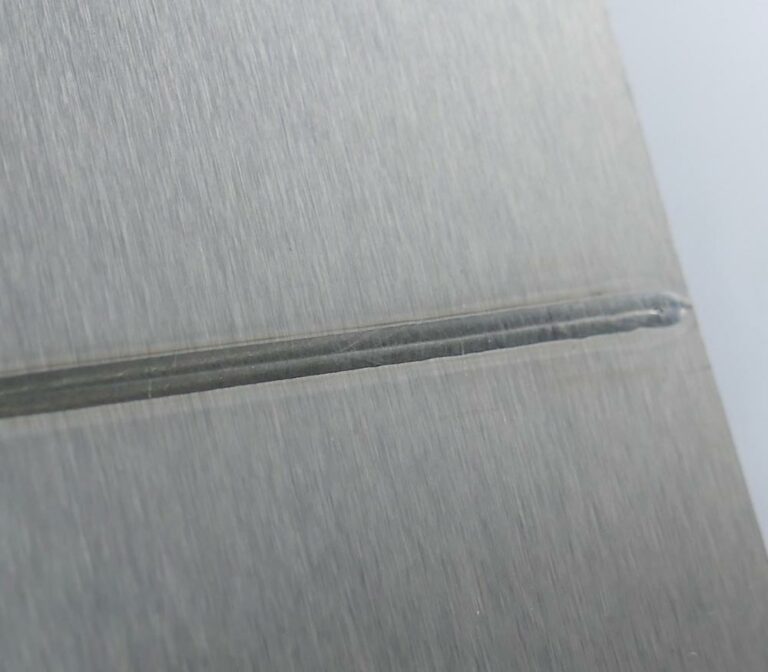

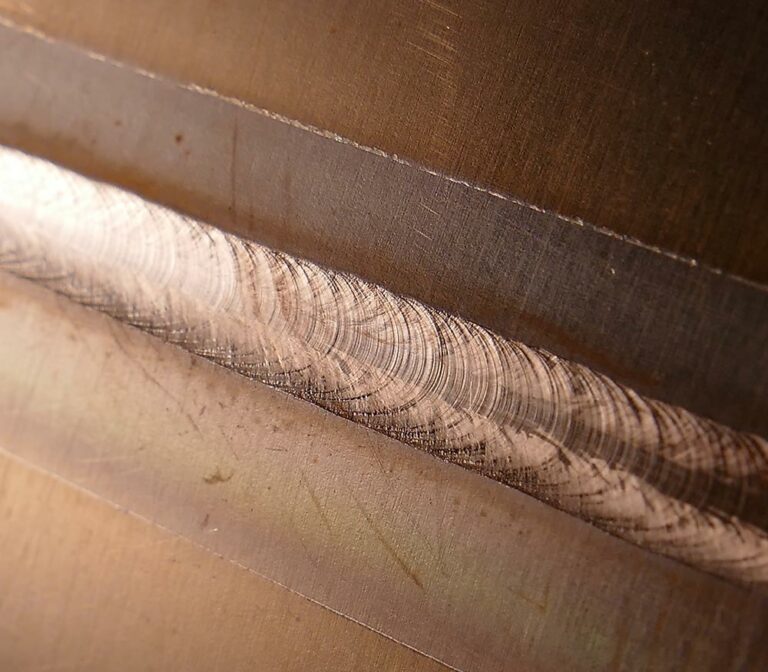

Perfection

Welds together

1980

0

Completed projects

Completed projects

0

Enthusiastic customers

Enthusiastic customers

0

motivated employees

motivated employees

0

Export countries

Export countries

2025

February 28, 2025

Schnelldorfer Maschinenbau at the STOM 2025 in Poland

January 14, 2025

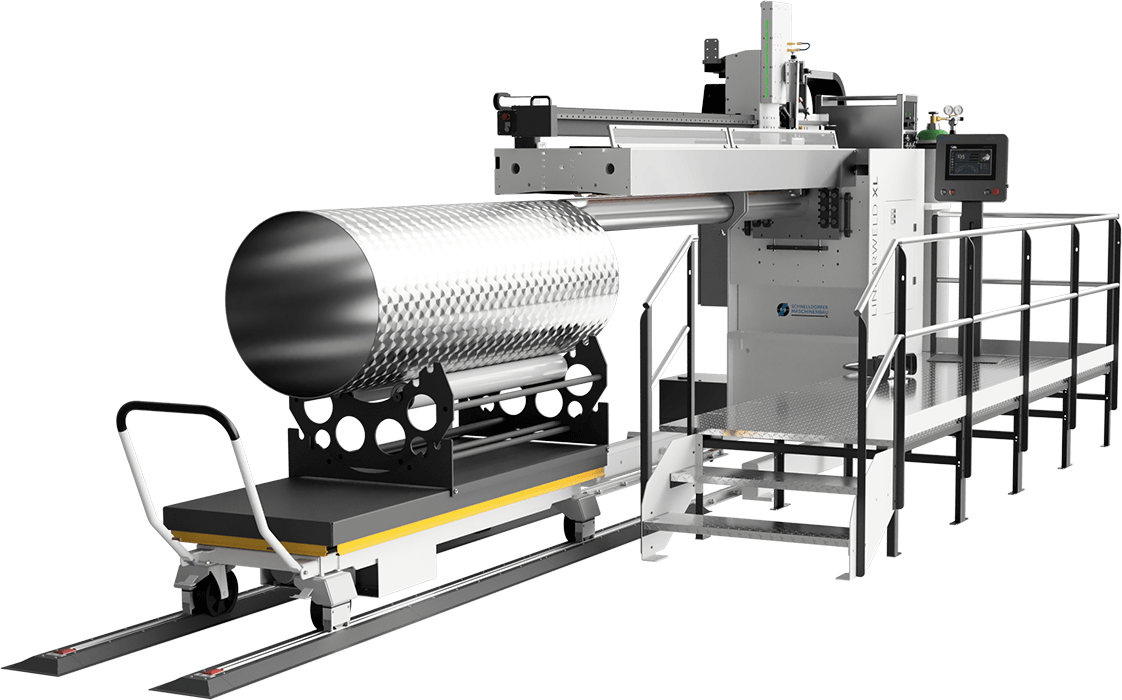

Schnelldorfer Maschinenbau becomes part of the Guttroff Group

February 9, 2024

A successful year 2023 summarized

February 6, 2024

Launch of our new website

February 4, 2024