A corner seam welding machine is required precisely when two sheets meet at right angles. This is the case with housings, frames or containers, for example. Here, the machine takes over the welding of the edges fully automatically and creates clean and consistently even seams. This saves time, especially where high precision and repeatable quality are required. Whether in one-off or series production, a corner seam welding machine is the smartest solution for stable joints - without any tedious re-welding.

Filter products

What is a corner seam welding machine?

A corner seam welding machine securely welds two sheets together at right angles, i.e. at a 90-degree angle. In contrast to machines for circumferential or longitudinal seams, it brings the sheets into position "leg to leg" and fixes them with clamping devices. The welding torch moves evenly over the entire length of the seam during welding and creates consistently high-quality weld seams thanks to the constant welding current, stable voltage and automatic wire feed. This produces particularly clean results with little rework - even when different operators or changing welding tasks are in use.

Depending on the model, the machine works with alternating current (AC) or direct current (DC), usually at a mains voltage of 230 volts. It is operated via a touch panel, a foot pedal to start and stop the welding process and integrated control software (PLC).

CORNER series - The corner seam welding machine for the highest demands

At Schnelldorfer Maschinenbau you will find the CORNER series, which has been specially developed for precise and productive corner seam welding jobs. It impresses with its sturdy design, which works reliably even with intensive use. Clamping devices hold the sheets in position without gaps, resulting in clean weld seams, while the integrated control system continuously and automatically regulates all important welding parameters such as amperage, voltage, wire feed and speed. This saves time during production and also guarantees consistently high quality with every seam.

You have the choice between the following models:

- CORNER ONE

- CORNWELD 300/500

- CORNWELD N-Safe

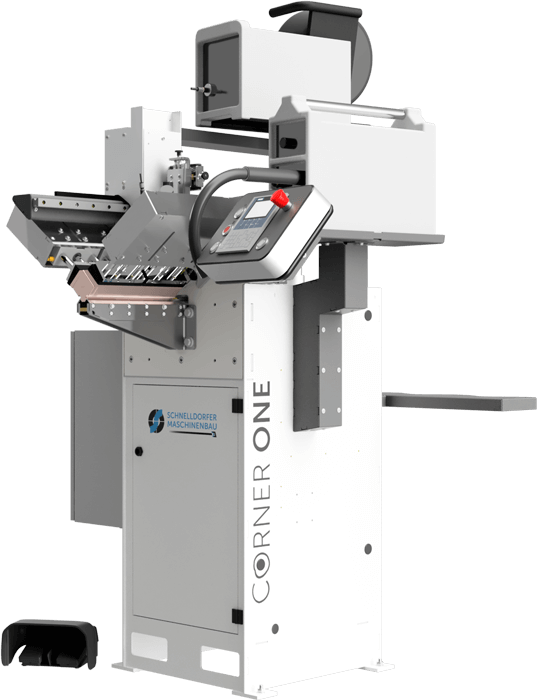

CORNER ONE

CORNER ONE is particularly suitable for simple or rear corner welds with welding lengths of up to 160 mm or 320 mm. It processes material thicknesses of around 0.5 to 3.0 mm and is therefore ideal for materials such as stainless steel, steel, galvanized steel or aluminium. Thanks to finely adjustable clamping devices and a precisely guided welding torch, the CORNER ONE can produce high-quality weld seams suitable for visible surfaces with minimal reworking.

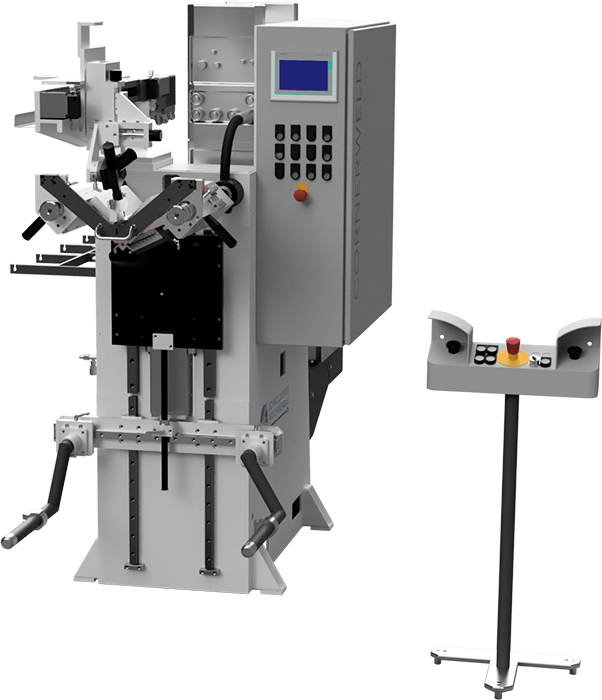

CORNERWELD 300/500

These CORNERWELD machines are designed for more demanding components with welding lengths between 300 mm and 500 mm. They can be used flexibly for material thicknesses between 0.4 and 3.0 mm and flange heights of up to 80 mm and also impress with their integrated water cooling and shielding gas supply. As a result, the welding process is stable throughout - even with complex geometries. Typical applications include switch cabinet construction, catering and hygiene technology as well as rectangular housings and cassettes.

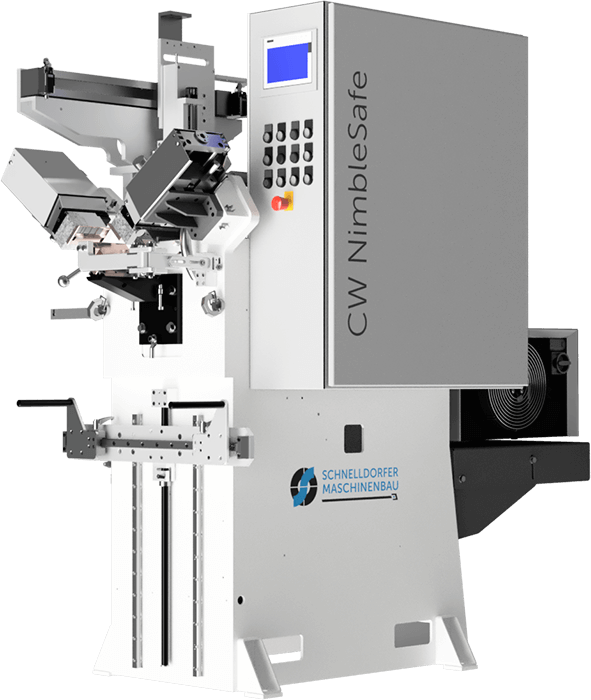

CORNERWELD N-Safe

The CORNERWELD N-Safe is equipped with a special safety linear clamping system and is therefore particularly suitable for delicate or sensitive components. It impresses with short set-up times, modular quick-change systems and simple operation - perfect for frequently changing component geometries. It is used, for example, in laboratory construction, for stainless steel housings and for products with increased safety and hygiene requirements.

State-of-the-art technology for precise corner seams - how CORNER welding machines work in detail

The CORNER series promises reliable welding technology in use at all times - both in one-off production and in series production. It combines the best technology with an intelligent and user-friendly control system.

Technology, handling and quality - that's what makes the CORNER series so special

Typical areas of application

Corner seam welding tasks can be found wherever components are joined at right angles: These include, for example, frames, housings, hoods, rectangular containers, cassettes and much more. The CORNER ONE is ideal for individual parts and small batches with varying material thicknesses, while CORNERWELD models work particularly efficiently with standardized part families. Whether control cabinet doors, hygiene assemblies or aluminum cassettes - the machines create clean weld seams and deliver consistently reliable results.

Operation and control - welding can be this easy

The controls of the CORNER welding machine are clearly structured and user-friendly. You can easily select familiar welding processes such as MIG, MAG or TIG using the touch panel. With the stored welding recipes, all parameters can also be loaded automatically and repeated and used as often as required. The welding process itself usually starts via the foot switch, while PLC-supported control software controls the welding current, wire feed, voltage, speed and arc. So every seam is a success.

Clamping devices and workpiece fixtures

The high-quality clamping devices fix every workpiece quickly, precisely and without great effort - with hold-down clamps as well as stops or modular jaws. This ensures that the seam remains gap-free and uniform throughout, even with varying sheet thicknesses or lengths. A water-cooled clamping area is also available for heat-sensitive parts to prevent distortion or loss of quality.

High welding speed meets quality

Depending on the process, material and thickness, CORNER machines can achieve welding speeds of up to 2,500 mm/min. The good thing is that the sophisticated and robust mechanics guarantee that the welding quality remains constant even at high cycle times. This shortens the production time immensely in some cases - and is a plus for economic efficiency.

Safety and ergonomics for the operator

From arc monitoring and light curtains to the controlled extractor unit - the CORNER series puts safety and health in the workplace first. That's why it impresses with an ergonomic working height and an all-round well thought-out machine design that always makes operation comfortable and minimizes physical strain. In addition, the display on the panel is clear and structured to minimize operating errors.

Results, materials and integration - all from a single source

What material thicknesses is the CORNER series suitable for? The CORNER series impresses with its diversity and is suitable for material thicknesses from 0.5 to 3.0 mm, whereby the thicknesses differ depending on the model and welding process. It can process virtually all common materials such as stainless steel, steel, galvanized sheet metal and aluminium.

MIG, MAG, TIG and plasma - these welding processes are available

- MIG (Metal Inert Gas Welding): Welding process with inert shielding gas such as argon. Ideal for non-ferrous metals such as aluminum.

- MAG (metal active gas welding): Uses active shielding gas such as CO₂. Particularly useful when welding steel and steel alloys.

- TIG (tungsten inert gas welding): Very precise process with non-melting electrode. Perfect for optically clean, thin weld seams on stainless steel and sensitive materials.

- Plasma: A variant of TIG welding with a focused arc for particularly fine and controlled welds, even in demanding applications.

A plus in results, quality and repeat accuracy

With the corner seam welding machine from the CORNER series, you can achieve uniform, tight and visually appealing weld seams. The high repeat accuracy reduces rejects and promises reproducible quality - no matter how often you change the material, welding task or operator. This makes the CORNER series perfect for industrial processes where consistent quality and predictable processes are required.

Schnelldorfer Maschinenbau - The professionals for your welding jobs

Schnelldorfer Maschinenbau has stood for quality "Made in Germany" since 1980: We supply the corner seam welding machine you need, equipped with a well thought-out design, high user-friendliness and practical, clean mechanics. We support you from the planning stage through to integration into your production line. We commission the machine on site and connect it to the PLC, QA systems and peripheral devices. Of course, we also adapt it precisely to your conditions and requirements.

But that's not all: our service continues afterwards, as we teach your team how to operate the machine properly with professional training courses, while our stock of over 5,000 spare parts ensures that your corner seam welding machine will never stand idle for long. Our professionals are always there for you, even when it comes to maintenance or support.

So don't hesitate: simply get in touch with us by e-mail, phone or via our form for a non-binding initial consultation - we look forward to hearing from you and your project!

Frequently asked questions (FAQ)

What types of components is the CORNER series suitable for?

The CORNER series is suitable for virtually all right-angled components such as frames, housings, covers or rectangular containers and processes them even with variable lengths and sheet thicknesses.

Can I use different welding processes such as MIG, MAG and TIG in one machine?

Yes, the corner seam welding machines in the CORNER series support the MIG, MAG and TIG welding processes, depending on the equipment. The welding parameters are simply selected on the touch panel and monitored via the PLC/control software.