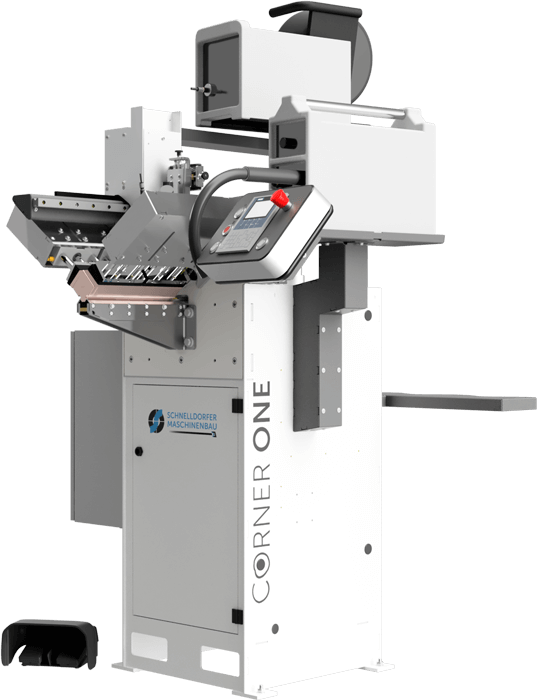

With the CORNER ONE, welding single and rear corner seam profiles becomes an experience of speed and precision. Every welding process is a masterpiece of technology, manufactured in Germany with attention to detail and a passion for perfection. The result? Work that is not only impressively fast, but also more precise than ever before - and all without tedious reworking.

Immerse yourself in the future of welding with CORNER ONE and experience the power and emotion in every seam.

CORNER ONE

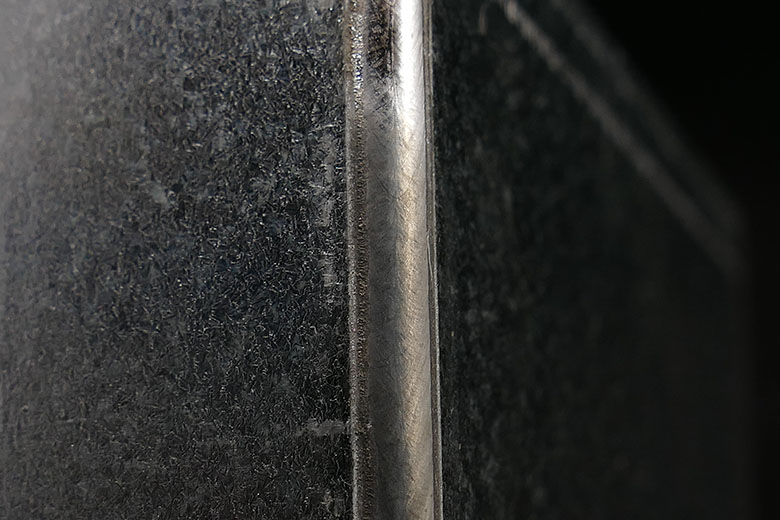

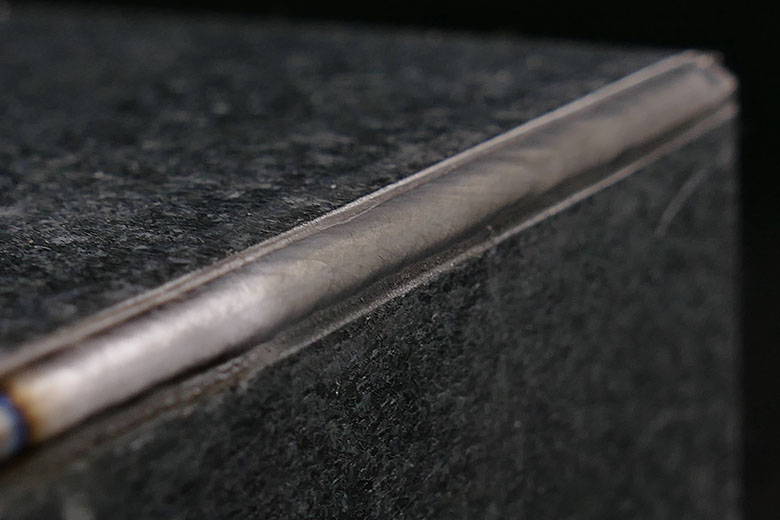

Sample parts

The most economical way to weld

"Maximizing Efficiency, Minimizing Costs: Weld Smarter with Generation ONE."

Cost efficiency

Best performance and results with significantly lower investment costs

Time saving

More efficient use of production time thanks to simple handling

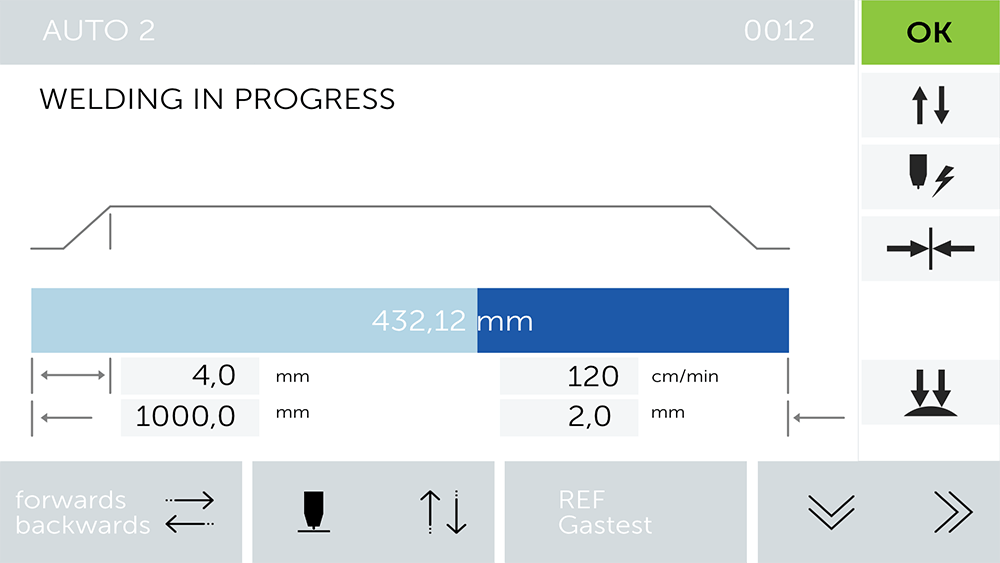

Visualization

Simple operation thanks to visualization of the basic operating options

Availability

Reduction of non-productive time and downtime thanks to high-quality machine processing

Delivery time

Shorter delivery times thanks to consistent implementation of standardization processes

Different sizes, different needs

Machine capacities

Give your production an upgrade!

If you really want to make a convincing case for the benefits of our CORNER ONE, you need to consider the time required for reworking when welding by hand.

The CORNER ONE eliminates the need for any reworking of the weld seams. This means that the average time saving during the entire process is a sensational 89 percent! This means that you only need 11 percent of the usual time for the component.

In other words: If you opt for manual welding with subsequent post-processing instead of using our CORNER ONE, you will need 900 percent more time. This is certainly completely unreasonable from a business perspective.

Discover more!

Visit our YouTube channel for a variety of exciting videos.

From product presentations to expert tips, we have it all for you.

Let us inspire you!

ONE

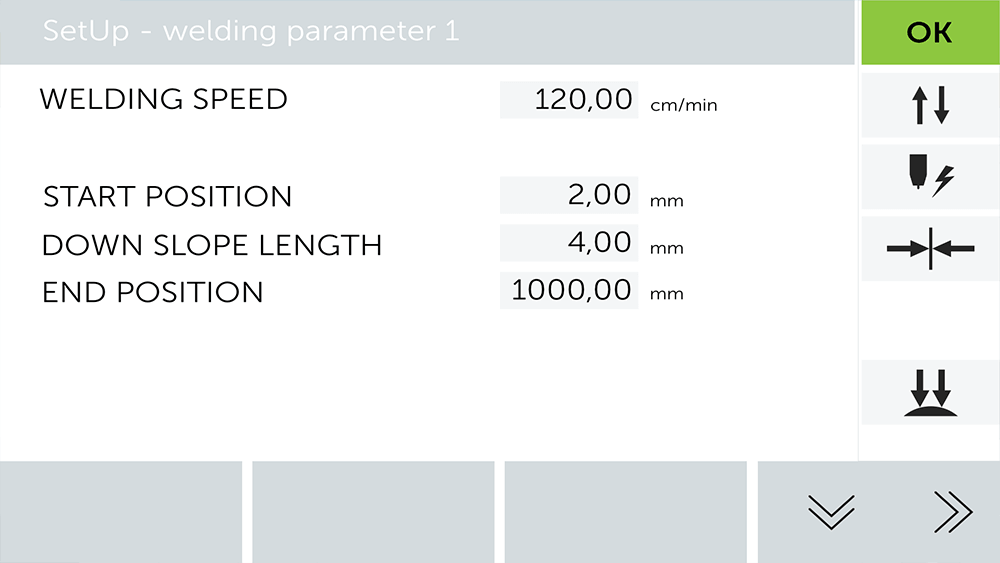

Discover the future of welding machine control with our Generation ONE.

Generation ONE redefines welding machine control by relying on start/stop signals - the simplest and most cost-effective way to optimize your production processes.

With our innovative technology, we enable precise control of your welding machines by activating operation exactly when it is required. The result? Reduced operating costs, less wear and improved energy efficiency.

Thanks to its user-friendly integration and customizable configuration, Generation ONE is the ideal solution for any production environment. Increase the efficiency of your operation and reduce your costs at the same time - with our Generation ONE welding machine controller.