Perfection

Welds together

Remote Support

Get in touch with us! Our team not only understands your needs, but can also anticipate them. They are in close contact with the factory support team to quickly resolve any software issue and minimize your production downtime.

Wear parts / tools

Our in-house tool design and manufacturing team can handle any application required. This enables us to offer shorter delivery times and, above all, a turnkey service. We have full control over the production process! 100% designed and manufactured by SMB.

Spare parts / maintenance

Our parts worldwide in the shortest possible time! SMB has a stock of more than 5,000 parts that respond to our customers' daily orders, from mechanics to electronics to pneumatics... All of which can be shipped within 48 hours to maximize the availability of your machines.

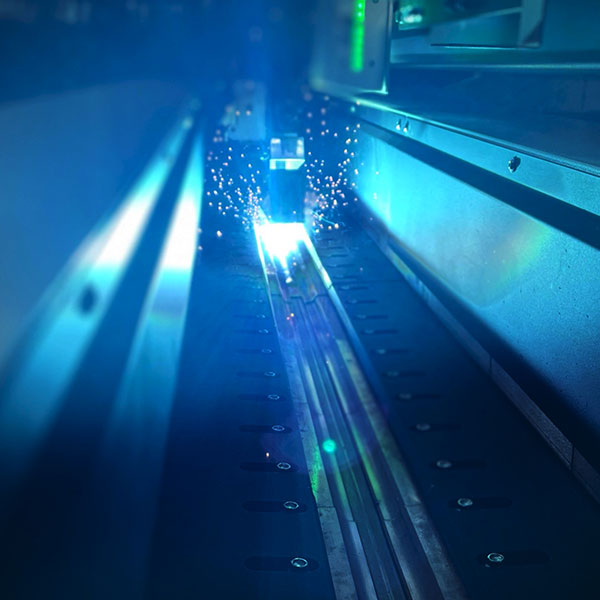

Welding support

Our experts offer professional welding technology support to optimize your processes. We strive for the highest quality standards and efficiency through comprehensive analyses and customized solutions. You can rely on our experience to optimize your welding processes.

Maintenance of HEISS machines

HEISS Maschinenbau GmbH has been part of Schnelldorfer since August 2020. By taking over the company, we have ensured that maintenance and customer service for the numerous HEISS machines will continue to be guaranteed.

Send request

If you need support with your machine or have any queries, you can contact us here.