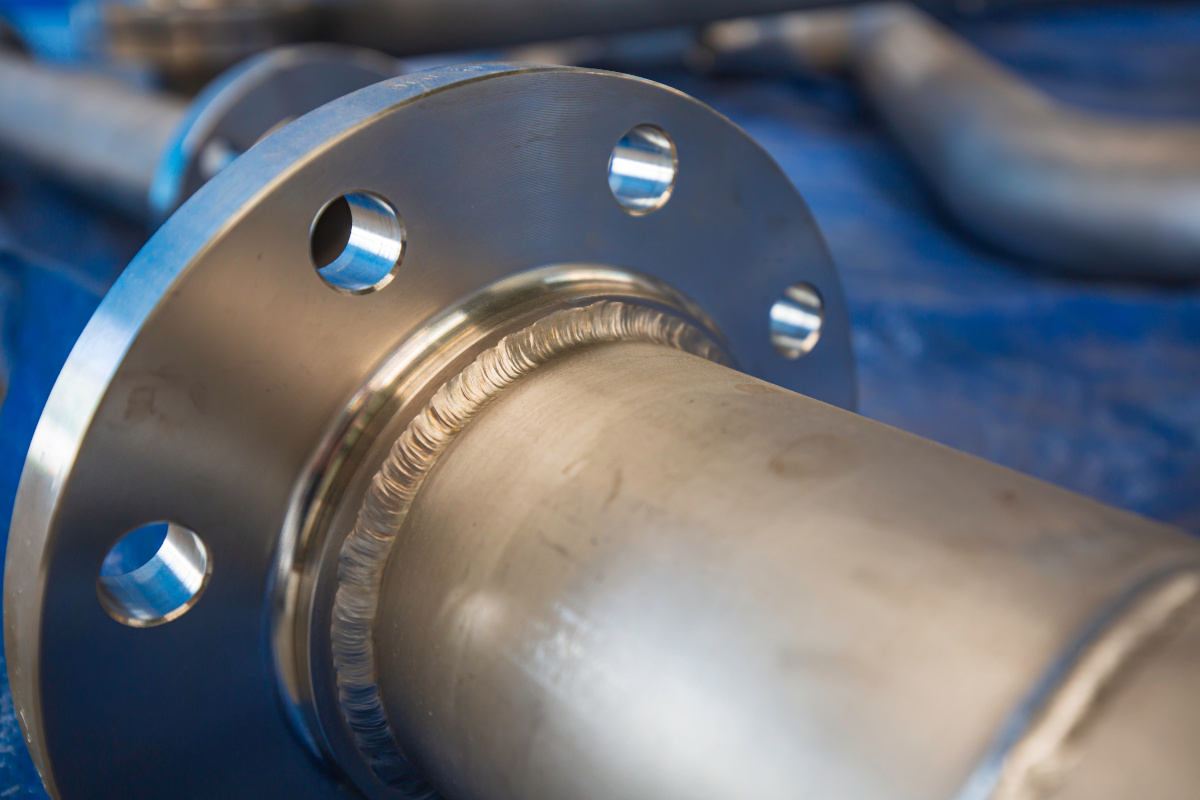

Flange welding creates tight and highly resilient joints – wherever safety and absolute tightness are required. Whether water, oil, or gas pipes, industrial plants, or high-pressure systems: the quality of the weld seam has a decisive influence on the operational safety and service life of the entire structure. Only with precise preparation, the appropriate welding process, and modern welding technology can joints be produced that reliably withstand even high pressures and extreme temperature fluctuations. Schnelldorfer Maschinenbau shows you what is important in flange welding.

Flange welding – fundamentals, areas of application, and key requirements

Flange welding is used to permanently connect flanges to a pipe or other metal components in order to create a secure and tight pipe connection. This is particularly important in areas where water, oil, gas, or natural gas are transported under high pressure or at varying temperatures. the quality of the weld seam is important. A carefully executed connection prevents leaks, minimizes downtime, and significantly increases the overall service life of systems.

Typical areas of application for flange welding range from plant and power plant construction to the chemical, pharmaceutical, and process industries. Flanges are used in a wide variety of shapes, sizes, and wall thicknesses: they range from simple steel pipes to sophisticated systems made of stainless steel, aluminum, or copper. The good thing is that with the right welding processes and automated solutions from Schnelldorfer Maschinenbau, reproducible weld seams with high tightness and consistent quality are created—even for large series and complex geometries.

Preparing flanges correctly – seam preparation, chamfering, and precise alignment

Before the actual welding process begins, preparation determines the success or failure of the weld. Everything around the flanges, pipe ends, and adjacent areas must be clean, dry, and free of oil, grease, oxide layers, rust, dust, or chips. The rule is: only with a clean surface can you reduce the risk of cracks and porosity.

Seam preparation also includes precisely adjusting the ends and correctly designing the groove. If the wall thickness, gap dimension, or surface quality are not correct, the tightness of the connection can suffer enormously. Careful preparation is therefore the basis for every high-quality weld seam—regardless of whether you are working with steel pipes, stainless steel, or aluminum.

Depending on the material and wall thickness, different chamfer shapes are also used. The correct chamfer facilitates welding, reduces the consumption of filler material, and at the same time improves strength and penetration.

Alignment of the flange – The basis for a precise pipe connection

The flange must be positioned at a right angle to the pipe so that all screw holes later fit precisely to the mating flange side. To achieve this, the position and height are usually fixed using clamping devices, collar holders, or special alignment tools, as this is the only way to counteract misalignment and deformation, which would otherwise have a negative effect on tightness and operational performance. Important to know: Even small deviations can later lead to leaks, uneven bolt loads, or problems when tightening the connection.

Welding flanges – step by step to a tight pipe connection

A clear procedure for flange welding is helpful in order to always achieve the best results. The following structure serves as a practical guide for flange welding:

- Preparation

Check the pipe and flange for damage and clean them thoroughly. Then prepare the seam—for example, by deburring, grinding, or adjusting the bevel. At the same time, select the appropriate welding process, filler material, and shielding gas, such as argon or mixed gases. The type of material, wall thickness, and subsequent operating conditions determine the parameters here.

- align

Place the flange on the pipe, move it into the correct position, and align the screw holes with the mating flange. With a stable fixation, the position is maintained throughout the entire welding process.

- stapling

Place several short tacking stitches around the circumference, evenly spaced, so that the component remains stable and the components do not shift against each other when heated.

- welding out

Apply the fillet weld or, if specified, the root and cover layers evenly. Ensure smooth guidance, constant welding parameters, and even heating so that the weld retains a continuous structure.

- Cool down and check

Allow the joint to cool down in a controlled manner and then evaluate it visually or, depending on requirements, using non-destructive testing methods.

Welding processes for flanging – TIG, MIG/MAG, SMAW, and flash butt welding

Various welding processes with different strengths are used for flange welding. TIG welding is often chosen when a particularly clean and precise seam is required. Since the welder can control the weld pool very precisely, TIG is particularly suitable for stainless steel, aluminum, and other sensitive alloys. It is often used in root layers, thin-walled pipes, and wherever a technically and visually flawless seam is required.

MIG/MAG welding, on the other hand, is significantly more productive and is therefore preferred for medium and larger wall thicknesses. The continuously fed welding wire and a stable arc allow flange-to-pipe connections to be made efficiently, even across multiple layers. SMAW (stick welding) is also particularly practical when robust processes are required for outdoor use or repairs, as it requires little equipment and works independently of a gas supply.

For high-strength pipe connections—such as in pressure pipes or plant engineering—burn-off butt welding or classic butt welding is also frequently used. These processes produce a very uniform connection across the entire cross-section and are designed for long-term strength.

Which welding method is used when?

This is closely related to the type of bevel. I, V, X, U, or J bevels require different approaches, as they each produce different weld pools and penetration depths. In contrast, simple fillet welds or butt welds are sufficient in many cases for socket welds and slip-on flanges. The team of experts at Schnelldorfer Maschinenbau is happy to answer any questions you may have about the various welding methods.

What is the most difficult type of welding?

TIG welding in pipe positions such as 6G is particularly challenging. Torch positioning, filler material feed, movement, and temperature must all be precisely coordinated—a task that requires experience and a good feel for the material and the entire process.

SMAW and manual welding technology

The SMAW process is a manual welding process that is still used in everyday industrial applications. The advantage of this technology is that flanges, pipes, plates, and other metal parts can be joined quickly and safely with manageable equipment, many electrode variants, and a stable arc. SMAW is a robust and particularly flexible solution, especially in situations where automated systems cannot be used, such as on construction sites, during repairs, or in service applications.

However, manual welding requires a high degree of experience, as everything related to the distance and movement of the torch, the choice of electrode, the control of the weld pool, and the handling of heat and oxidation are directly interrelated. Schnelldorfer Maschinenbau therefore transfers these basic skills to automated welding technology. The powerful welding systems enable repeatable processes and consistent quality, which pays off especially in series production for flange welding.

Overview of typical combinations of chamfers and welding processes

| Bevel type | Typical wall thickness | Preferred welding methods | Typical application |

| I-phase | Thin plates/sheets up to approx. 5 mm | TIG, MIG/MAG, manual arc welding | Simple pipe connection, short seams |

| V-groove or V-chamfer | Approx. 5–15 mm wall thickness | MIG/MAG, TIG, SMAW | Common flanges and pipes in plant engineering |

| X-phase | > 15 mm wall thickness | MIG/MAG, submerged arc, TIG | Highly stressed connections under pressure |

| U-phase | > 20 mm, thick-walled pipes | TIG (orbital welding), MIG/MAG | High-quality piping with high requirements |

| Throat seam or simple bevel | Variable wall thickness | MIG/MAG, TIG, SMAW | Slip-on and socket weld flanges, slip-on flanges |

Flange welding with Schnelldorfer – welding with precision and quality

For decades, Schnelldorfer Maschinenbau has been synonymous with high-quality welding technology that has proven itself in all areas. We combine practical machine development with in-depth knowledge, placing particular emphasis on precision, repeatability, and durable solutions. This is precisely the basis on which we create automated welding systems that can be flexibly adapted to materials, component sizes, and production cycles and produce consistently high seam quality—regardless of the operator or shift. Our systems stand for shorter setup times, less rework, and a lower error rate. For quality and cost-effectiveness that pays off.

Don't hesitate to contact our team of experts. We will accompany you from the planning stage to the finished system, always with honesty and on equal terms. We look forward to hearing from you!

Frequently asked questions (FAQ)

How do you weld a flange to a pipe?

The pipe is inserted into the flange, aligned, and fixed in place with evenly distributed tack welds. This is followed by continuous fillet welds on the outside and, depending on the design, on the inside, until a tight connection is achieved.

Which weld seam for pipes?

Flanging usually involves fillet welds. For pipe-to-pipe connections, however, butt welding is recommended. The appropriate method always depends on the material used, the wall thickness, and the required quality.