When things literally have to run smoothly, the right rotary welding machine makes all the difference. Schnelldorfer Maschinenbau therefore only supplies you with the best models from the powerful ROTAWELD D series. The machines create even and distortion-free weld seams on thin-walled pipes and complex cylindrical components - for quality, precision and genuine service straight from Bavaria. Find out here what a powerful circumferential seam welding machine has to offer.

Filter products

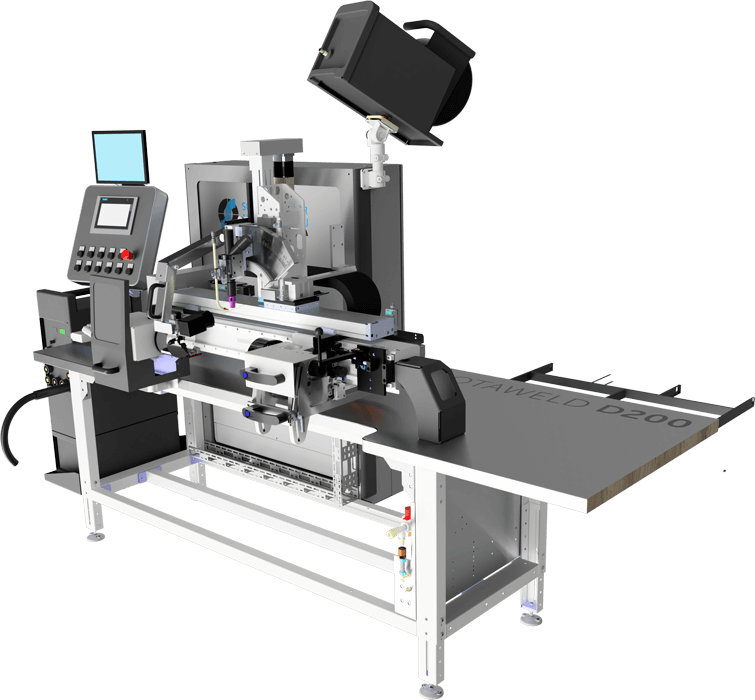

Circumferential seam welding machine

ROTAWELD D-Series

What is a circumferential seam welding machine?

With a circumferential seam welding machine, you can weld round or cylindrical metal parts safely and precisely. In contrast to the longitudinal seam or corner seam welding machine, which performs straight seams along flat sheets or at corners, the workpiece rotates around its own axis here. The welding head remains stationary throughout. Circular seam welding machines are mainly used in tank and pipeline construction, where they process pipes and cylinders with a diameter of 20 mm or more.

The ROTAWELD D series from Schnelldorfer Maschinenbau

Our ROTAWELD D-Series stands for precise welding with consistently high quality. The machines in this series are specially designed for rotationally symmetrical workpieces such as pipes, containers and cylindrical components with a diameter range of up to 400 mm and a maximum weight of 30 kg. The pneumatic tailstock is particularly practical here, as it makes workpiece pick-up particularly secure and positioning and adjustment much easier. The welding head is guided precisely to the workpiece with the aid of a servomotor. This enables uniform movements, even for components with complicated shapes. Thanks to their modular design, all ROTAWELD D machines can also be adapted to the requirements of different industries and easily integrated into existing production lines. This gives you the welding solution you need: reliable, flexible and guaranteed to work to a high standard.

Generation BASIC - Machine control made easy

The machines in the ROTAWELD D series are equipped with our exclusive BASIC control system. This control technology allows you to get started quickly and intuitively: it features a clear text display, integrated power source and simple navigation. This allows you to control your welding processes conveniently, efficiently and without any unnecessary programming effort. Convenience and performance in one.

Design and function of the welding machine

Frame, tailstock and cross support

The ROTAWELD D series from Schnelldorfer Maschinenbau is based on a stable, low-vibration machine frame. This ensures that all welding processes run smoothly and precisely - even with sensitive or thin-walled workpieces. The pneumatic tailstock with a 50 mm stroke ensures secure fixing. However, an electro-pneumatic version is also available depending on requirements. In combination with the finely adjustable cross support, every component can be precisely aligned and welded. This means that every rotationally symmetrical workpiece, from thin-walled tubes to cylindrical containers, stays in place.

Welding head, torch and torch stand

The welding torch - whether TIG or plasma - is mounted on a cross support that can be flexibly and precisely adjusted to the workpiece. With the height-adjustable torch stand, the torch always works at the optimum distance from the workpiece. All important parameters such as welding current, feed speed and torch position can be conveniently controlled via a servomotor. The result is uniform and clean weld seams for every application and every product.

Control and degree of automation

The ROTAWELD D series is controlled via a modern PLC/HMI solution with a 7-inch Siemens Comfort Panel. Here you can save all welding parameters as recipes, which makes working on recurring components or series production much easier. The automatic torch movement, an optional remote maintenance unit and clear user guidance further simplify operation. This gives you consistent quality with minimum effort.

From TIG to plasma - these are the welding processes

The RODEWELD D-Series has two powerful welding processes:

- the proven TIG process

- and the advanced plasma process.

The TIG process is used when particularly clean and precise circumferential seams are required. This is the case, for example, with visible seams or sensitive components made of thin-walled stainless steel. The low heat input ensures that the material retains its shape at all times. Soft plasma welding, on the other hand, is used for demanding materials. This process allows even difficult-to-weld materials to be joined precisely and with little distortion. Where conventional welding techniques reach their limits, plasma welding gives you the highest seam quality with a perfect connection.

Circular welding machines are used here

The circumferential seam welding machines from Schnelldorfer Maschinenbau are used wherever round or cylindrical components need to be joined permanently and precisely by welding. In pipeline construction, for example, they are used for welding tanks, pressure vessels and pipelines. In apparatus and mechanical engineering, on the other hand, they are perfect for a wide variety of assemblies with round geometries. The machines are also used in the automotive industry for the production of exhaust systems, while in metal construction they create a secure connection for round pipe constructions such as supports, boilers, T-pieces and pipe outlets. In short: Wherever uniform and tight weld seams are required in combination with maximum precision and process reliability, you are ideally equipped with the circular seam welding machine.

Schnelldorfer Maschinenbau - Your partner for systematic welding

Schnelldorfer Maschinenbau, based in Schnelldorf, Bavaria, has stood for high-quality welding technology made in Germany since the 1980s. Our team of welding engineers develops modular welding solutions for all requirements and a wide range of industries. Our service does not end with the delivery of your circumferential seam welding machine - on the contrary: our experienced team supports you during commissioning, carries out process tuning and trains your personnel directly on site to familiarize them with the new technology. We can also take care of assembly and programming on request - so that you can go into production as quickly as possible. For maintenance, servicing or quick help with technical questions, we are also available by phone, remote access or in person. And should you ever need a spare part, we can draw on our extensive stock of over 5,000 items and send it to you within 48 hours.

Let us find your new circumferential seam welding machine together and integrate it into your company: Get in touch with us - we look forward to hearing from you!

Frequently asked questions (FAQ)

For which workpieces is a circumferential seam welding machine suitable?

Our circumferential seam welding machines are ideal for cylindrical workpieces such as pipes, flanges or container halves. The machines can process diameters of up to 200 mm.

What level of automation do PLC-controlled rotary welding machines offer?

With PLC controls including recipe management, servo-electric infeed and Siemens Comfort Panels, our systems can be operated fully automatically. This gives you consistent welding quality with high quantities and minimal effort.

Which welding processes are available?

With the ROTAWELD D series, you have the choice between TIG and plasma welding processes. Both processes promise maximum precision and performance, create strong weld seams and master even the most demanding welding.

How fast is the delivery and commissioning time?

The complete assembly and commissioning of your circumferential seam welding machine is carried out in close consultation with you, but always as quickly, efficiently and reliably as possible. For more information, please contact us at any time.